Contact us

- Linker Screens ( United States) Sales representative

-

Contact Person:Bo Wu

E-mail: Bo.wu@wedgewirescreen.com

Cell:+1 (818) 620-9624

Fax:1-859-201-5804

Add:3206 Ruby Wilmington DE 19810. USA

- Linker Screen(Reactor internals&Tower internals)Sales engineer

-

Contact Person: Sandy

Email:sales.linker@cnlinker.cn

Cell:+86-189-6221-7189

Fax:+86-512-58281345

Add:Z1811 Cathay Plaza No.19 Renmin Road(E), Yangshe Town , Zhangjiagang City, Jiangsu Province,China

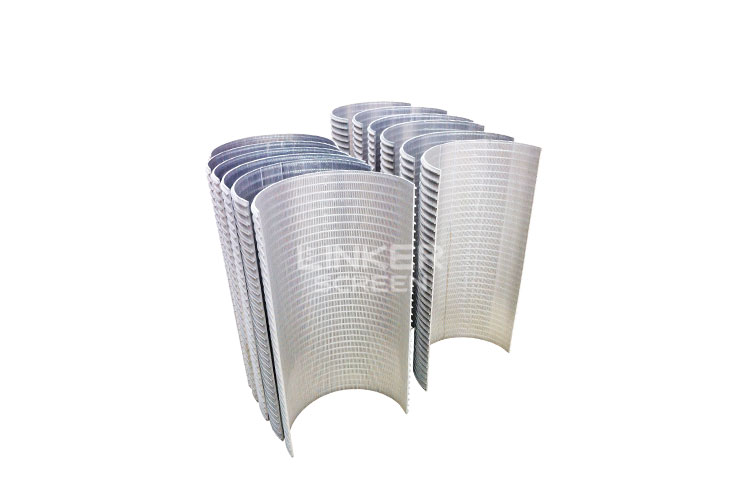

sieve bend screen

pressure curved screen

We manufacture sieve bend screens according to customer’s requirements, such as curved screen, DSM screen, static screen,120 deg screen and etc., and we have our own R&D team, we design CAD drawing of wedge wire screen to meet particular user’s needs, we manufactured DSM screen,120 deg screen ,curved screen, side hill screen,corn starch screen according to particular user’s needs.

Sieve Bend Screens can be manufactured in a variety of widths, arc lengths, slots or wedge wires to suit the flow rate and material being separated. Although most applications require Static Sieve Bends, “Cross Flow”, “With Flow” and “Vibrating” Sieve Bends can also be manufactured.

These screens are found in industries such as:

1、Bio-fuels

2、Brewing

3、Corn wet milling

4、Ethanol

5、Malting

7、Starch

8、Sugar

Sieve Bend Screens have another name as DSM screens, a sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

The dewatering capacity of a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width).

Screening efficiency and solids capacity are directly related to the length (arc length). Longer arc lengths should be considered for feed containing a high percentage of solids.

Sieve Bend Screens can be manufactured in a variety of widths, arc lengths, slots or wedge wires to suit the flow rate and material being separated. Although most applications require Static Sieve Bends, “Cross Flow”, “With Flow” and “Vibrating” Sieve Bends can also be manufactured.

These screens are found in industries such as:

1、Bio-fuels

2、Brewing

3、Corn wet milling

4、Ethanol

5、Malting

7、Starch

8、Sugar

Sieve Bend Screens have another name as DSM screens, a sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

The dewatering capacity of a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width).

Screening efficiency and solids capacity are directly related to the length (arc length). Longer arc lengths should be considered for feed containing a high percentage of solids.

- Gap:0.02-8.10mm

- Length:200-6000mm

- Nominal diameter: Can be customized according to customer’s requirements

- Tolerance clearance:±0.1mm curing 120°

- Material: 304、304L、316、316L、904L、2205、2507、hastelloy-c276,etc.

- Mesh selection: wedge wire mes

- Treatment: Pickling

Preview:sieve bend screen

Next:gravity curved screen