Contact us

- Linker Screens ( United States) Sales representative

-

Contact Person:Bo Wu

E-mail: Bo.wu@wedgewirescreen.com

Cell:+1 (818) 620-9624

Fax:1-859-201-5804

Add:3206 Ruby Wilmington DE 19810. USA

- Linker Screen(Reactor internals&Tower internals)Sales engineer

-

Contact Person: Sandy

Email:sales.linker@cnlinker.cn

Cell:+86-189-6221-7189

Fax:+86-512-58281345

Add:Z1811 Cathay Plaza No.19 Renmin Road(E), Yangshe Town , Zhangjiagang City, Jiangsu Province,China

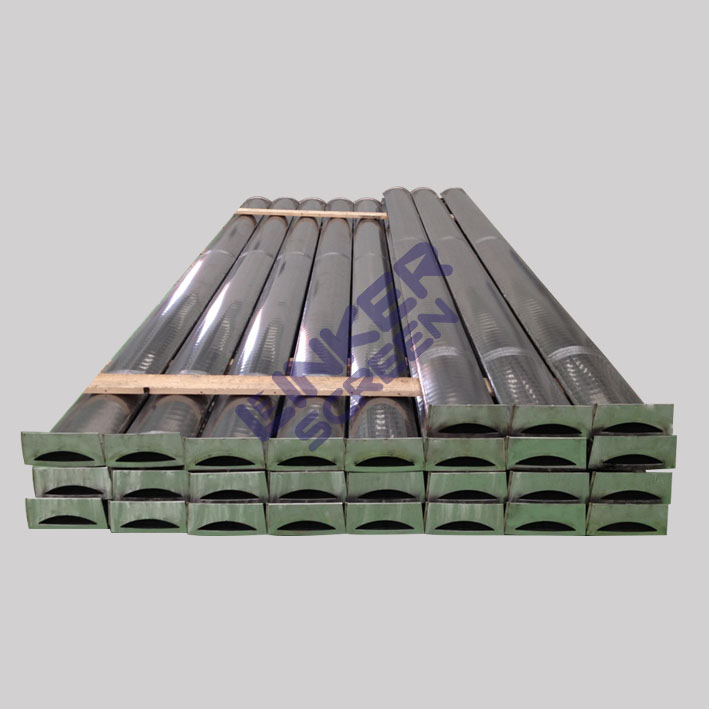

Scallops

Scallops assembly is forming the outer screen component of a radial flow system. Their general shape is extending parallel to the inner vessel wall. Their inner surface delimits the outer side of the catalyst bed. They are usually installed inside vertical reactors and they distribute or collect the flow. Cover deck is closing the gap between inner screen component and scallops. Flow direction can be out-wards or inwards. Scallops are usually introduced through the vessel top manhole. They are standing on a support ring attached to the vessel wall.• Scallops are standing against the inner vessel surface as hollow conduits distributing/collecting the gas flow from their inner side. Each one is placed adjacent to the next one as part of the scallops-set. Each scallop cross section is handling a flow rate which is parallel to the scallop’s axis with a flow capacity limited to the cross section area. Total reactor capacity is the sum of all individual scallops flow rate. applications such as Gas treatment, Platforming, reforming, CCR, ammonia converter, styrene, etc.Nav